Copenhagen Atomics, a Thorium Molten Salt Reactor startup in an unlikely location

A visit to Denmark

Originally published at Independent Online

Photo:Left: Thomas Jam Pederson, co-founder of copenhagen atomics, Right: Hügo Krüger

In the late 20th century, Denmark experienced a surge in anti-nuclear sentiment that ultimately led to the 1985 Moratorium with over 60% of the Danish voters opposing the construction of new nuclear facilities. Against this historical backdrop, it’s then rather surprising that Denmark has unexpectedly become a focal point for introducing advanced nuclear technologies such as Thorium Molten Salt Reactors (TMSR) to the world market.

The origins of the Molten Salt Reactor trace back to the early days of nuclear research, when Dr. Alvin Weinberg’s team conducted experiments on an experimental reactor at the Oak Ridge National Laboratory from 1965 to 1969. They demonstrated the feasibility of using molten fluoride salts as both the fuel and the coolant in a nuclear reactor. Unfortunately, the project was shut down by the Richard Nixon administration, because of the widespread growing opposition to nuclear energy in the United States of America, as well as the competing interest from alternative energy sources who leveraged the politics of the day to their benefit.

Unlike conventional pressurised water reactors, which use water as a coolant, MSRs utilise either an uranium and thorium salt mixture that offers inherent passive safety features and enhanced thermodynamic efficiency. In conjunction with other concentrated salt technologies, the MSR can serve as both a battery storage solution and a generator of electrical power, making it the ideal technology to aid in decarbonization as nations aim to move away from fossil fuel reliance within this century. Notably there is a superior energy rate of return where theoretically one gram of thorium or uranium salt can replace a ton of oil.

In February 2024, I visited the facilities of Copenhagen Atomics at the invitation of one of the DeepTech company’s four co-founders, Thomas Jam Pederson where I spent 2 days on their factory floor to see what the startup was all about. Their facility is full of stainless steel components and there are dozens of engineers tinkering with the metals and instrumentation, trying out various configurations to make the Molten Salt Reactor a reality.

Photo: Display of instrumentation, gaskets and other stainless steel components being tested

Copenhagen Atomics operates with a unique business model that distinguishes it from other nuclear reactor startups. Incidentally, it already has a product line ready, because instead of solely focusing on theoretical designs to convince the regulators, the company prioritises practical applications with potential spin-offs that can be sold to other industries.

The related industries with which they have contracts include seawater desalination, nuclear fusion, and various physics departments of universities that are interested in studying the molten salt test kits. Notably they landed a contract with the Texas based Abilene Christian University and one of their backers include Rod Adams, a former US Nuclear Submarine Operator, blogger, turned venture capitalist.

Photo: The Advanced Lab Test Kits that are being sold to Universities across the world.

However, the challenge with molten salt reactors is not the underlying nuclear physics, which is well established, it’s rather the chemical properties of the salt. Corrosion Control, even with stainless steel, requires careful management of salt purification and metal selection. Copenhagen Atomics is ideally located to draw from Denmark and the wide Scandinavian region’s experience in shipbuilding, desalination technology and corrosion control. Incidentally, the company’s entrance hall greets visitors with a stainless steel heat exchanger that was developed in parallel with the shipping industry.

Photo: Stainless steel heat exchanger

Copenhagen Atomics’s business strategy is to target the broader energy sector. They recognise that a significant portion—85%—of global energy consumption is not consumed as electricity. Their TMSR that will be cocooned in a steel container will provide industrial heat to customers. Their ambition is to have a production line ready with thousands of plug and play reactors ready for their customers. They will assist them in adapting the heat for industrial applications such as hydrogen production, chemical synthesis, steelmaking, cement manufacturing, as well as electricity generation. The DeepTech startup has already preempted the regulators by integrating defence in depth and passive safety systems inside of their design.

Surprisingly, most of the design work to get the product to market is not nuclear in nature. It is the classical mechanical, structural and electrical engineering that involves iterative testing on the metal behaviour. Within their factory floor, there are numerous apparatus such as metal testing kits used to evaluate the behaviour of the FLiNaK Fluoride Salt—a mixture of lithium, sodium, and potassium. Ten of these metallic test kits are made annually, followed by a design review to determine if improvements are needed.

The material properties of FLiNaK are comparable to uranium and thorium salts. FLiNaK is low-cost and has a low safety profile and therefore it is the ideal material that can be used to train engineers as they prepare for the nuclear reactor phase of the development. The purity of the salt is essential, as increased temperature, impurities in the process, and lack of Moisture control, can easily accelerate the corrosion process. Therefore, careful control of the salt is necessary at high temperatures and all instrumentation and control equipment have to be developed for this purpose.

Copenhagen’s tactic to get their reactor developed is clear, they follow a three-phase reactor strategy: the first reactor operates on water only, the second on FLiNaK that is heated to 600 degrees Celsius. And finally a third reactor is under construction that will be used to test natural uranium and thorium salts. The latter will be complete around the end of 2026. What makes this process unique is that until the third reactor operates, there is still no radioactive handling involved and therefore the process of engaging with the regulator can be launched in parallel as the nuclear development continues.

Photo: Phase 1 Reactor: Heat exchanger

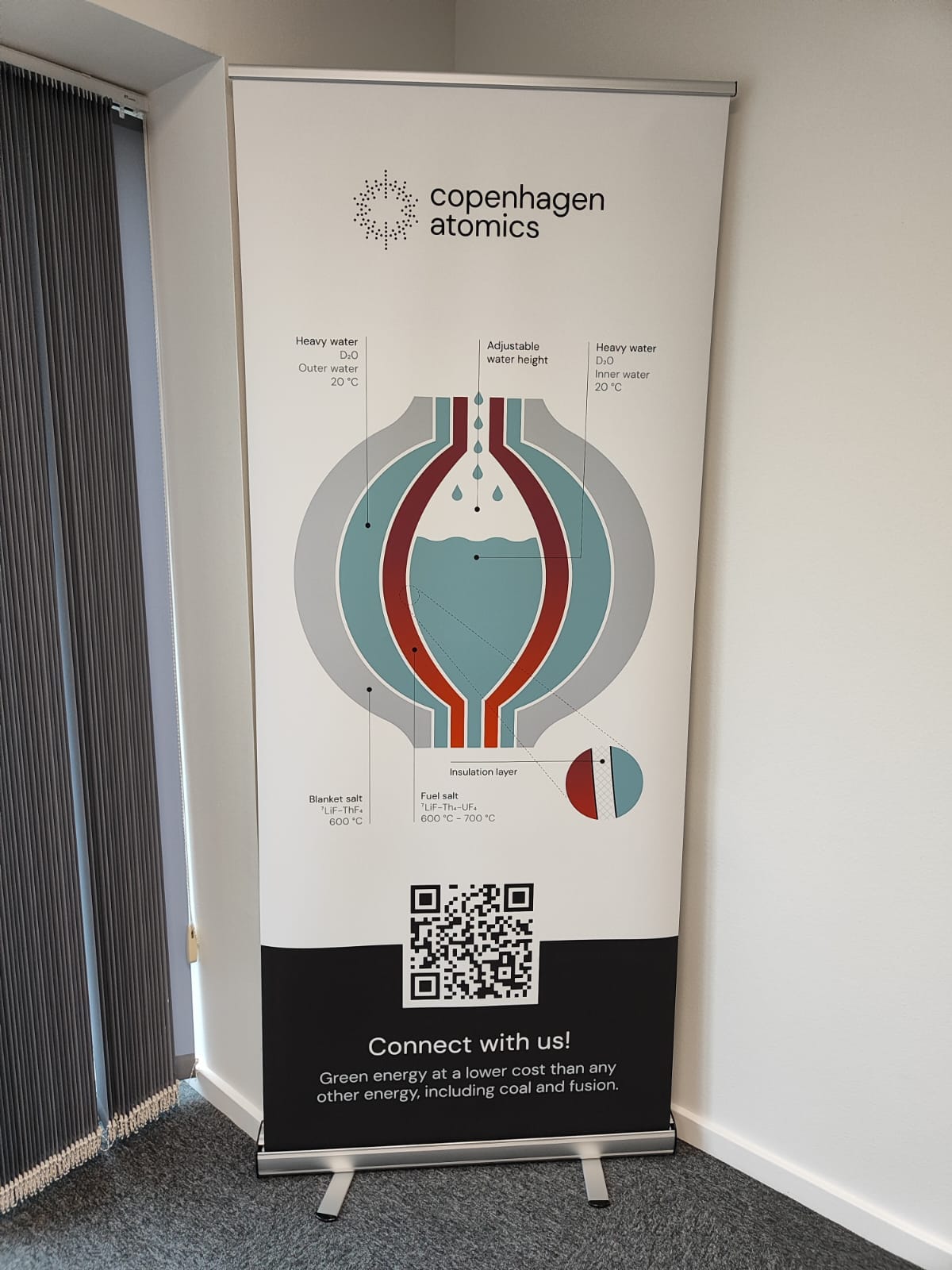

The final reactor design will eventually incorporate heavy water as a moderator instead of graphite - that is traditionally used by other Small Modular Reactor (SMR) startups. Even though it is more expensive, heavy water is selected due to its passive safety features and long-term durability, as it does not suffer from irradiation damage or degrade for at least 100 years.

Photo: Copenhagen Atomics Reactor Concept

Furthermore throughout the lab there are various cylinders of nitrogen and argon that are used to protect the primary and secondary components. Throughout their various iterations they have figured out that gaskets are better welded shut than to maintain the purification of the salt - as well as the ability of the metal to keep the moisture and oxygen out.

Photo: Thomas Jam Pederson illustrating the tests used to get the corrosive behaviour under control

Lastly, they even have a production facility for material purification that requires materials for the reactor to operate such as Lithium-7 and Lithium-6. Both isotopes are respectively required in the nuclear fission and fusion industry.

With this focus to get material behaviour under control while simultaneously selling the development as spinoffs, Copenhagen Atomics have managed to escape various commercialisation valleys of death. They have a business model that allows them to obtain learning curves, while simultaneously generating cash flow by selling what they learn from the process to various clients.

When I questioned Thomas about the apparent contradiction of being based in Denmark, he responded straightforwardly, that what their politicians do is irrelevant, because Denmark is not viewed as a primary customer. Copenhagen Atomics believes that inventing and developing new technology requires the right people and resources and that ultimately geographic location is irrelevant. As the product reaches its maturity, the clients are already knocking on the Danish door.

I am wanting to say a report on MSRs I read a dozen years ago also blamed the US defense industry (pre Nixon) for the real setback for thorium reactor research. The argument was that the Pentagon wanted a dual use fuel that would also serve nuclear weapons development, so the big bucks back then didn't flow to playing around with thorium.

The stainless steel fittings are Dairy couplings as well as the heat exchangers. I know, I worked for the Danes many moons ago in the food and beverage sector.

The Danes are clever with some who are very nice people, but also there are many fools who have emotional reactions like those falling for the the 1985 Moratorium on Nuclear. Mind you the Krauts in Germany did the same with Nuclear plants, except they shut the working ones down. Germany was once an intelligent nation. No so much now.